Do You Want to Try 3D Printing Vacuum Cleaner Accessories?

- Cici

- 4 days ago

- 4 min read

The Rise of 3D Printing Technology and Its Household Applications

3D printing technology has surged in popularity in recent years. While it may sound like cutting-edge tech confined to labs or factories, it has already made its way into ordinary homes. You can use it to print moving dinosaur toys for kids, replacement parts for discontinued items, custom handicrafts, model aircraft, and even small wearable accessories. Although 3D printing demands precision and accuracy, operating a home 3D printer is not particularly complicated. If you're a DIY enthusiast, creative maker, or figure and collectible lover, getting one could open up a world of possibilities for you.

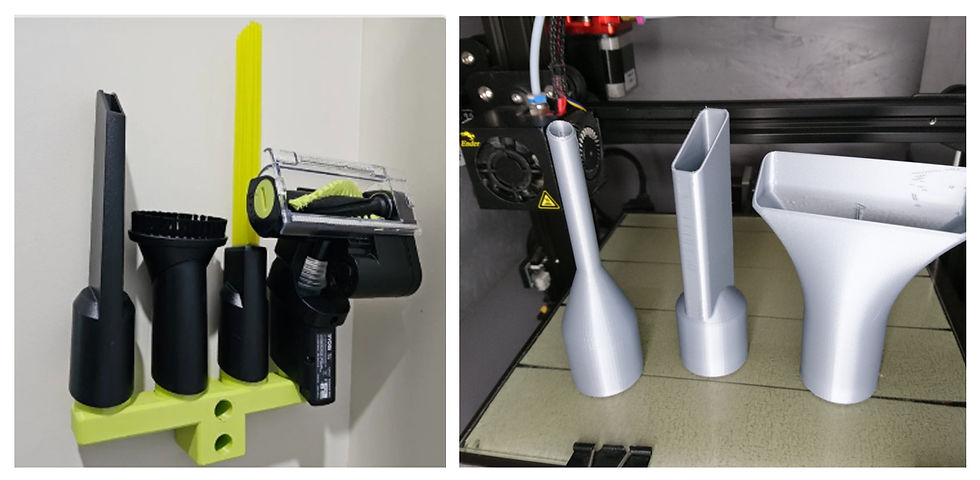

The Practical Uses of 3D Printed Vacuum Cleaner Accessories

Building on the everyday applications of 3D printing, one particularly useful area is creating household items. Many people print vacuum cleaner holders or various types of vacuum cleaner brush heads. The key advantage is the ability to customize the appearance to your preferences while meeting specific functional needs. However, the downsides are clear: you'll need modeling skills and hands-on post-processing work. If you're simply looking to avoid the high cost of official accessories, you can opt for third-party options from manufacturers like techTongBo. Today's technology is mature, and the performance of these accessories is often comparable to originals.

Preparations Needed for Making 3D Printed Vacuum Cleaner Accessories

To start printing vacuum cleaner accessories, proper preparation is essential. First, you'll need a high-quality 3D printer that's stable, reliable, and relatively quiet. Next come the printing filaments—these are like the paints in traditional art. The most common and beginner-friendly options are PLA and PETG, which are the easiest to print and the most affordable. With a higher budget, you can explore ABS, TPU, or even nylon. The printing difficulty increases in this order: PLA < PETG < TPU < ABS < nylon.

Each material has distinct characteristics:

PLA is easy to print and eco-friendly but has poor heat resistance;

PETG offers PLA's ease of use combined with better impact resistance and strength; TPU is flexible and elastic, ideal for soft parts;

ABS provides heat resistance and toughness but is prone to warping;

nylon excels in strength and wear resistance but is highly hygroscopic and requires careful handling.

You'll also need some supporting tools, depending on your budget and needs. Basic ones include pliers (for removing supports), a flush cutter or hobby knife (for smoothing surfaces), a lighter (to eliminate stringing), glue (for assembling parts), and vacuum compression bags with a pump (for storing filament).

More advanced tools might include a hot glue gun (for bonding), a rotary tool or Dremel (for grinding), acrylic markers (for coloring), screwdrivers (for assembly), and a soldering iron (often used to heat-insert nuts).

Larger equipment like a filament dryer box (hundreds of dollars, though some use cheap food dehydrators instead), air purifiers, air quality monitors, or an enclosure cabinet (from simple shelves to custom aluminum extrusion builds costing over a thousand dollars) can be considered. Most of these are optional—choose based on your actual situation.

The Principle and Workflow of 3D Printers

Once your setup is ready, understanding how 3D printers work will help you operate them more effectively. The core principle is "layer-by-layer forming, building up gradually." A 3D digital model is sliced into numerous thin layers, which are printed one by one and stacked to form the complete solid object. This is similar to constructing a building: finish one floor, then move on to the next, continuing until the structure is complete. The printer follows digital instructions to deposit and solidify compatible materials (such as plastics, photosensitive resins, ceramics, rubber, or metal powders) layer by layer until a full 3D model emerges.

The workflow consists of three main steps: modeling, slicing, and printing.

Modeling

Modeling involves creating a digital 3D model of the object you want to print—this is the foundation of 3D printing, typically done with CAD software. This step can be the most challenging for beginners due to a lack of experience, making it hard to turn ideas into reality. However, newcomers don't need to worry too much. Plenty of 3D model websites now offer vast libraries of ready-to-use designs that cover most common needs.

Slicing

Slicing takes the 3D model and cuts it along the height axis into a series of 2D cross-sectional layers. Each layer includes the outline shape, infill details, and toolpath instructions for the printer. The key task is converting a standard STL file into a G-code file that the 3D printer can understand and execute.

Printing

After transferring the G-code to the printer, it follows the instructions to precisely move and deposit material layer by layer onto the build platform. The material solidifies quickly upon deposition, forming a solid layer. The process repeats rapidly for each subsequent layer until all slices are complete, resulting in a fully formed 3D object.

Pros and Cons of 3D Printed Vacuum Cleaner Accessories

With a grasp of the principles and process, let's evaluate the advantages and disadvantages of 3D printed vacuum cleaner accessories. The main advantage is the ability to create custom parts tailored exactly to your specific needs, offering unparalleled personalization. However, the drawbacks are significant: limitations in printer capabilities and modeling expertise often result in lower precision and rougher surfaces, making compatibility with the machine difficult. Even if they fit, issues like poor sealing, weak heat resistance, and easy deformation can arise. Moreover, the overall cost of 3D printing tends to be high—the printer itself may represent only a small fraction of your total expenses.

Summary

In conclusion, if you enjoy 3D printing as a hobby, feel free to experiment with printing simple vacuum cleaner accessories or basic storage solutions. But when factoring in time and overall costs, purchasing ready-made parts is often the smarter choice. techTongBo is a dedicated vacuum cleaner accessories factory whose products offer reliable quality at prices lower than originals, with a wide variety that fits most robot vacuums and vacuum cleaner brands on the market.

techTongBo (also named: Nanjing TongBo / NJTB) is a Chinese company specializing in the manufacture and sales of vacuum cleaner accessories. We offer replacement accessories for the global market that are compatible with mainstream vacuum cleaner brands and have stronger price advantages.

Comments